A. Solar Thermal Power

Its a pleasure and sense of pride to introduce the next generation technology in the domain of Solar Power Production, The ‘Super Critical Solar Thermal Power’ generation, employing the Indigenous State of Art Technology, the SCSTP. The operation methodology and apparatus of the said technology can ensure to operate the Power Plant up to 100% Plant Load Factor, to provide cheaper solar power and fast ROI. Along with the best possible utilization of natural resources, like land water etc. required for development of the utility.

Technical Feasibility:- The technology being harnessed by us in our super critical solar thermal power plant is far superior than that of conventional Solar Thermal Power Plants, thus increasing the conversion efficiency of the solar irradiation heat into electricity thereby reducing specific land requirement and cost of installation of the project. Thus the specific cost of generation is reduced enough to make it cost competitive with those of other sources such as coal, gas nuclear etc.

Environmental Benefits:- The project is environment friendly as it does not consume fossil fuel but also controls the thermal pollution of environmental as a result of lower heat losses in condensation/ cooling tower system than that of conventional steam cycle driven power plants of equivalent capacity. And if there is any objectionable effluent discharged that would be much lesser in comparison of conventional system.

Brief Description of the Technology

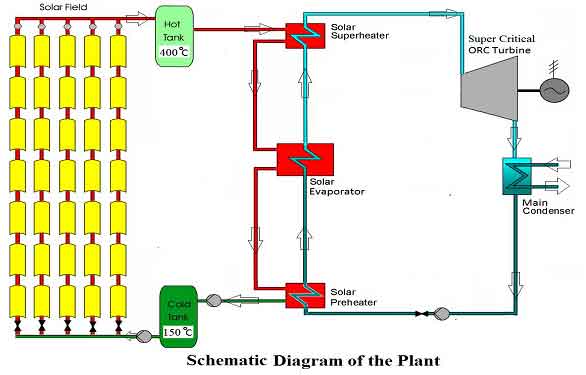

Parabolic Trough CSP Collection, Heat Storage System Coupled with Super Critical ORC evaporator Turbo-machinery

Description: - The process of power generation is completed in two distinct cycles, one is the HTF Cycle and other is the Working fluid cycle. Thus the process is known to be Binary Cycle Power Plant.

HTF Cycle: - Concentrated Solar Heat is collected in the parabolic trough solar field in a suitable Heat Transfer Fluid Sigma Therm-T (HTF) which is stored in HOT TANK of heat storage system. The heat may be stored in the HTF itself of some nitrate salts (60% NaNO3 + 40% KNO3). The stored heat is transferred to the evaporating Heat Exchangers to transfer energy to the organic working fluid and there from it goes into the COLD TANK of the heat storage system, from where it is recycled to the Collection Field, thus the first cycle is completed.

Working Fluid (Power) Cycle: - In the evaporating heat exchangers the working fluid is evaporated and super-heated up to its super critical parameters of pressure and temperature. The said working fluid is then used to turn the turbine and the extract of the turbine is channelized to the main condenser to reject its latent heat and converted into liquid state. Thus the liquid working fluid is then collected and recycled to the evaporating heat exchangers to repeat the cycle of power generation.

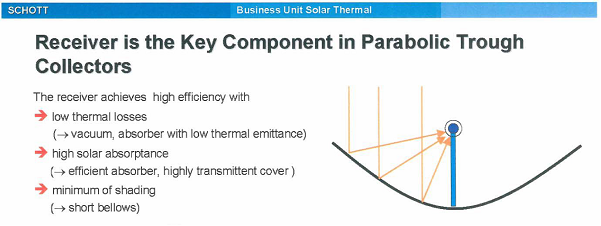

Solar irradiation is concentrated 80-120 times buy the Parabolic Trough Mirror shown above, on a receiver tube, which is situated in the focal line of a said Parabolic Trough Mirror, the said vacuum receiver tube attains high temperature, and the heat is thus picked up by a suitable Thermic Oil (HTF), flowing inside the receiver tubes, and channelized there-from to the HOT tank (about 400°C) of the Heat Storage System.

B. Bio-CNG Projects

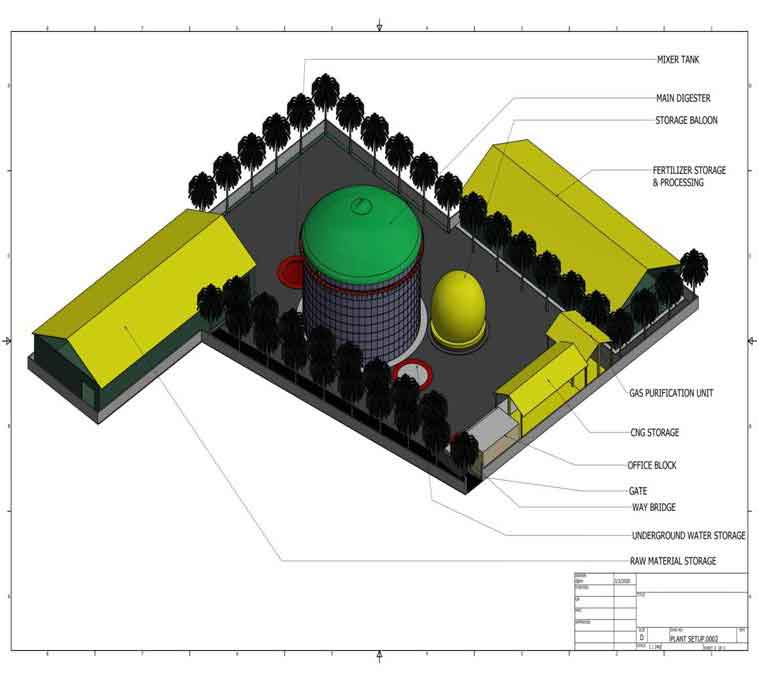

A non-polluting and renewable source of energy is obtained in a biogas plants. Under the process organic waste is converted to useful fuel. It is an excellent way of energy conversion. Automobile grade Bio-CNG can be produced from WASTE STUFF from Rural, Municipality, Fruit & Vegetable Market, and Agricultural Wastes, Food Processing Waste and any other Bio Degradable Waste. The waste is collected using special vehicles designed for transporting the wastes from nearby Farm, municipality and villages, in enclosed containers to prevent air pollution by the SPV. Cattle dung is collected from nearby villages used as inoculants. Biogas plants also produce ENRICHED ORGANIC MANURE.

ENVIRONMENTAL ASPECTS

It leads to energy security via conservation of natural resources (LPG, wood, kerosene, coal, etc.). The ENRICHED ORGANIC MANURE can be used as fertilizers. Liquid slurry is rich in micro & macro nutrients along with NPK and can be directly applied in fields. It leads to soil improvement due to high nitrogen contents. The environmental aspects of the project may be enumerated as

- The project has a low water footprint, as most of the process water is recycled.

- The project is zero discharge and provides valuable solid and liquid fertilizers, which recycle all the macro and micronutrients back to the soil.

- It reduces global warming by preventing fugitive emissions of methane from organic waste streams.

- For all these reasons, the project is entitled to excise and VAT exemption, tax breaks and subsidies.

- Bio-CNG Project provides improvement in the environment, sanitation and hygiene by proper management of waste.

- It improves ground water quality as anaerobic digestion provides several water quality benefits.

- Biogas digesters can destroy more than 90% of disease causing bacteria that can otherwise enter surface water. Thus it reduces risk to human and animal health.

ADVANTAGES AND BENEFITS OF BIO-CNG:-

- Biogas is eco-friendly fuel. Provides a non-Polluting and renewable source of energy.

- Has a calorific value of around 6kWh/M3—this is equivalent to half a liter of diesel.

- Larger biogas plants can generate and feed electricity into mainstream power grids.

- Efficient way of energy conversion.

- Saves women and children from drudgery of collection and carrying of firewood, exposure to smoke in the kitchen, and time consumed for cooking and cleaning of utensils.

- The digested sludge is high quality organic manure, completely natural and free from harmful synthetic chemicals. It can supplement or even replace chemical fertilizers.

- Leads to improvement in the environment, sanitation and hygiene.

- Provides a source for decentralized power generation.

- Leads to employment generation in the rural areas.

- Any biodegradable matter can be used as substrate.

- Anaerobic digestion inactivates pathogens and parasites, and is quite effective in reducing the incidence of water borne diseases.

- Environmental benefits on a global scale: Biogas plant significantly lowers the Greenhouse effects on the earth’s atmosphere. The plant lowers methane emissions by entrapping and using it as fuel.

- The project combines and synergizes state of art foreign technical knowhow and equipment with cost effective frugal engineering and balance of plant from INDIA.

C. Bio-CNG Filling Stations: -

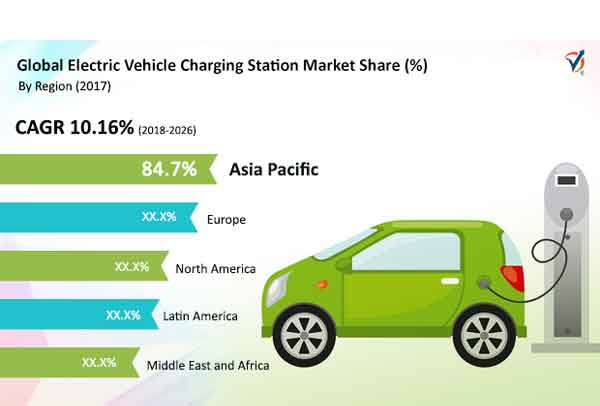

D. Electric Vehicle Charging Stations: -

E. Wind Power Project: -

F. Biomass Power Project: -